-

DIY Custom Personalized Design Sublimation Printing Blank White Baby Blanket

DIY Custom Personalized Design Sublimation Printing Blank White Baby Blanket

Item Name: Baby Blanket (70*100cm)Material: Flannel, soft and perfect for tender baby skinSize: 70*100cmReferential printing parameters: 180℃, 120SNote:other size also could be customized...

Detail -

Christmas Stocking

Christmas Stocking

...

Detail -

Christmas Ball

Christmas Ball

...

Detail -

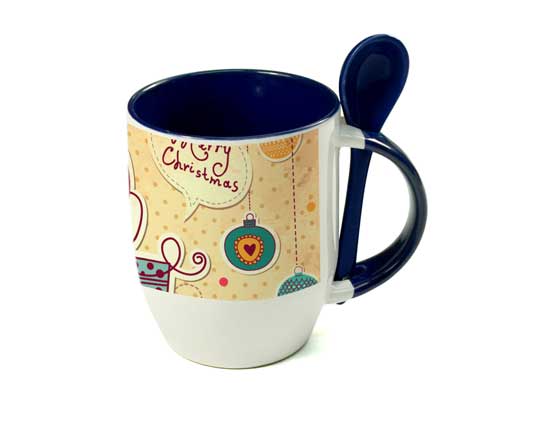

11oz Santa Claus Handle Mug

11oz Santa Claus Handle Mug

...

Detail -

350ml&500ml Sublimation Stainless Steel Milk Bottle

350ml&500ml Sublimation Stainless Steel Milk Bottle

Material:304 Stainess Steel Double WalledItem No:EX-SST-C04Color: Whitecapacity: 450ml 16ozSize:φ 8 8cm,H8 3cmWeight...

Detail -

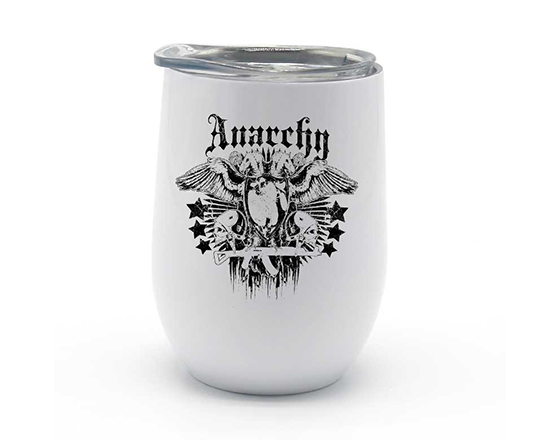

Sublimation Stainess Steel Bottle Starbucks Tumbler

Sublimation Stainess Steel Bottle Starbucks Tumbler

Material:304 Stainess Steel Double WalledItem No:EX-STColor: Whitecapacity: 300mlSize:Top Dia 8 2cm Bottom Dia : 6 5c...

Detail

-

12oz Mason Jar with Straw(Clear)

12oz Mason Jar with Straw(Clear)

tem Name: 12oz Mason Jar with Straw(Clear) Item No : EXGM-12 Weight: 15kg Packing: 36pcs ctn Dimension: 460*450*280mm...

Detail -

3oz Shot Glass Mug with Gold Rim

3oz Shot Glass Mug with Gold Rim

em Name: 3oz Shot Glass Mug with Gold Rim Item No : EXGM-06 Material: Glass Size: 3oz, 3 3cm bottom*3 9cm top*10 2cm height Weight: 18kg Packing: 144pcs ctn Dimension: 340*270*360mm...

Detail -

MDF Puzzle

MDF Puzzle

Item Name:MDF PuzzleItem No:HB-PZ-02Size:17*17cmShape:Square...

Detail -

MDF Photo Frame

MDF Photo Frame

Item Name:MDF Photo FrameItem No : PANEL-S E-9012705Shape:SquareDimension: 90*127mm...

Detail -

MDF Luggage tag

MDF Luggage tag

...

Detail -

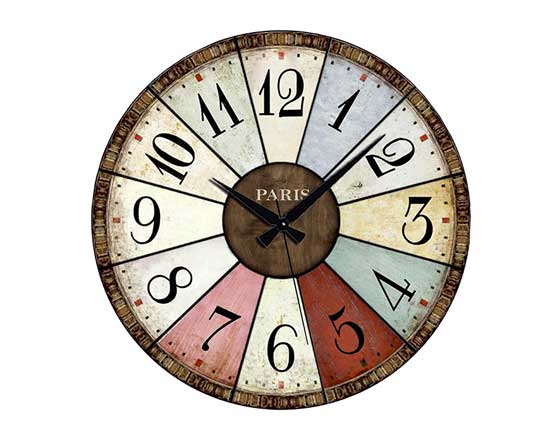

MDF Clock

MDF Clock

Item Name:MDF Clock Item No : EXAW-002Weight: 102gDimension: 170*170*5mm...

Detail